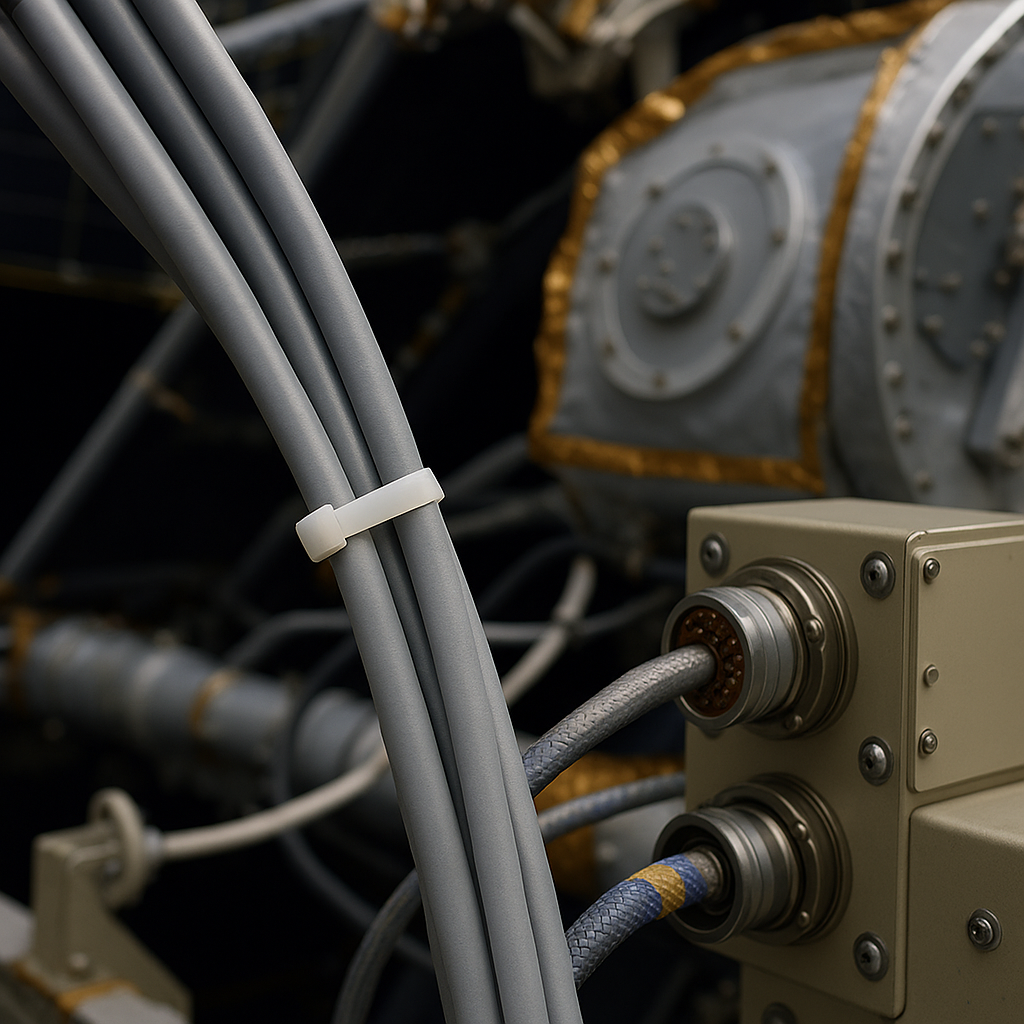

- Cable ties were first developed in 1958 by Thomas & Betts to organize wiring in aircraft manufacturing. Their first model was called the Ty-Rap — and it’s still in use today!

- The tiny ridges inside a zip tie’s head are designed like a miniature ratchet system — each “tooth” locks into place against the tie’s serrated edge, allowing it to tighten in one direction only and hold with surprising strength despite its simple design.

- From releasable and reusable ties to metal-detectable, heat-resistant, and color-coded versions, there’s a cable tie designed for nearly every industry — from gardening to aerospace.

- A single heavy-duty cable tie can hold up to 175 pounds (79 kg), depending on its width and grade. That’s stronger than many ropes of similar size!

- NASA has used special-grade cable ties made of Tefzel and other high-performance plastics to manage cables in satellites and spacecraft — because even astronauts need to stay organized.

- From sculptures to fashion pieces, artists around the world have used cable ties in creative ways — building everything from dresses and lampshades to full-scale installations.

- UV-resistant black cable ties are specially made to withstand harsh sunlight, rain, and temperature changes — making them perfect for outdoor projects or garden setups.

- Most people cut their cable ties after one use, but releasable designs or a clever use of a small pin can let you unlock and reuse standard ones without damage.

- Cable ties are used by first responders, campers, and mechanics as quick fixes — from securing broken straps to creating makeshift tourniquets in survival situations.

- Though often overlooked, nylon cable ties can be recycled and repurposed. Some companies are even developing biodegradable or eco-friendly alternatives to reduce plastic waste.

ZipTiesdotCom

Strong. Simple. Versatile.

Leave a Reply