Ever wondered how those simple yet super-useful cable ties (zip ties) are made? Here’s a peek behind the scenes

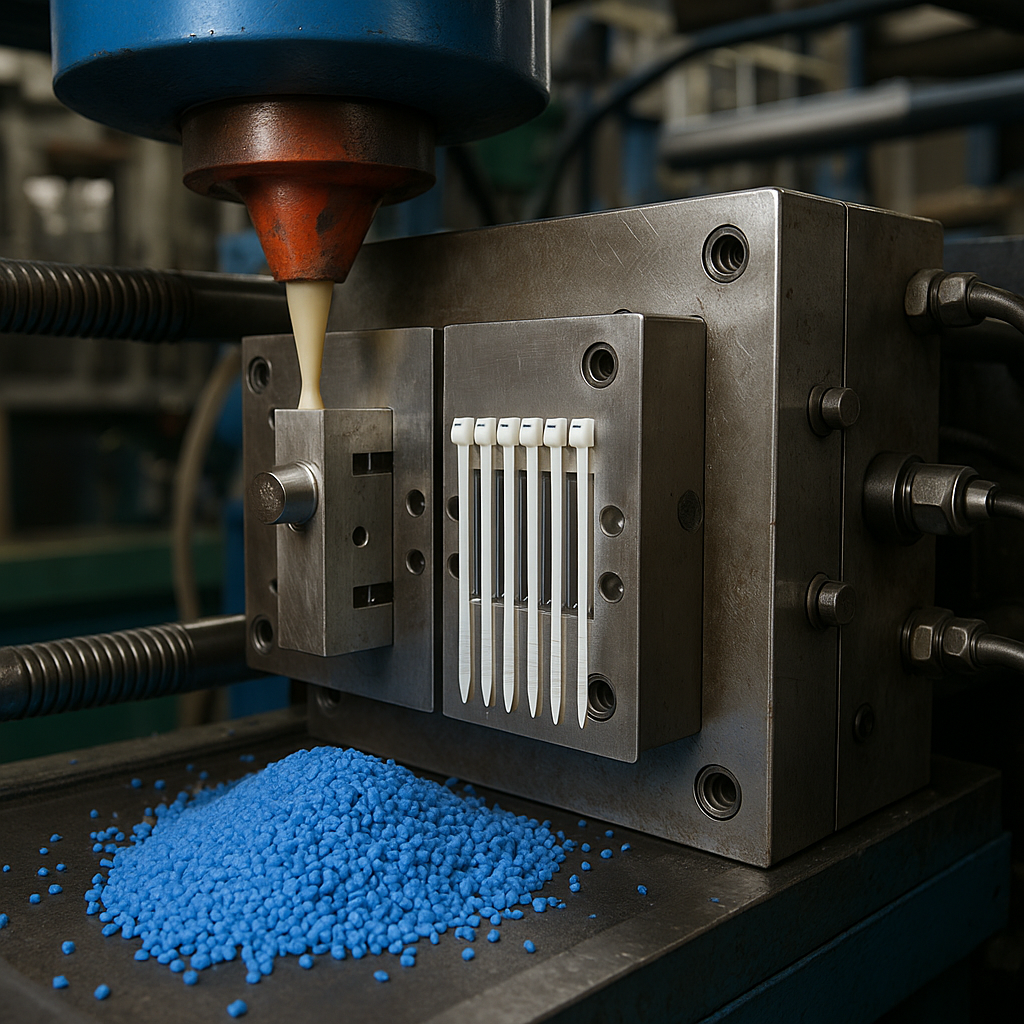

Raw Material — Nylon Pellets

It all starts with tiny nylon 6/6 pellets, a durable plastic known for strength, flexibility, and resistance to heat. These pellets are dried to remove moisture — because even a little water can weaken the final product.

Melting & Injection Molding

The dried pellets are fed into an injection molding machine, where they’re heated to around 250°C (480°F) until they melt into a thick liquid.

This molten nylon is injected under high pressure into steel molds shaped like the final cable tie — complete with the locking head and teeth.

Cooling & Ejection

The mold is then cooled with water or air to solidify the nylon. Once hardened, the mold opens, and the freshly formed cable ties are ejected automatically.

Trimming & Finishing

The ties are still connected by thin plastic runners from the molding process, so machines (or workers) trim and separate them. Any rough edges are smoothed out for safety and performance.

Quality Control

Samples are tested for tensile strength, locking performance, and temperature resistance. A good cable tie must hold tight without snapping — even under stress.

Packaging & Distribution

Finally, the finished cable ties are counted, packaged, and shipped to warehouses or stores worldwide — ready to keep cables, hoses, and countless other things neatly organized!

Fun fact: A standard cable tie can withstand up to 50 lbs (22 kg) of tension — not bad for a piece of plastic!

ZipTiesdotCom

Strong. Simple. Versatile.

Leave a Reply